PRODUCT CENTER

——

Details

Present Situation Of Chinese Mine Tailings

At present, China has accumulated more than 60 billion tons of various mine tailings, and the annual output has reached about 1.6 billion tons. However, the comprehensive utilization rate of tailings is only 18.9%. Most of them aren’t utilized comprehensively. In recent years, China values the comprehensive utilization of tailings increasingly. With increased exploitation of mineral resources, the discharge of tailings will increase every year. It has become an urgent task that the comprehensive utilization of tailings.

Qingdao Hesheng Intelligent Environmental Protection Equipment Co., Ltd. accumulation and development in tailings comprehensive treatment industry for many years, we have strong market competitiveness with experienced R&D team, advanced automated production equipments and many core technologies in tailings dewatering process. Our company's original tailings dewatering process has a low comprehensive cost, simple, stable and easy to operate. With excellent technical technology, excellent product quality, and complete product categories, the company customizes different equipments accord-ing to customer requirements to meet site requirements.

The Ways Of Comprehensive Utilization Of Tailings As Following

1. for tailings treatment problem, we can use advanced technology and reasonable process to re-select tailings so that the useful components of tailings can be recovered in a limited degree, which can reduce the volume of tailings;

2. tailings can be used as raw materials of building materials, such as making cement, cast stone, ceramsite, concrete aggregate, ceramic tile, glass, etc.;

3. tailings can be applied as filling materials of underground mine goaf, such as water sand filling materials or cemented filling aggregates. After tailings of ore-dressing plant is discharged, it is necessary to send the tailings preparation section for classification, and coarse sand is sent to the gob area, and fine stuff is stored in tailings storage;

4. tailings materials can be used to cover soil and land for planting crops or planting trees;

5. tailings materials can also be used to build roads, pavement materials and non-slip materials, etc.

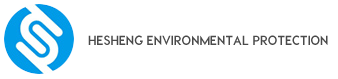

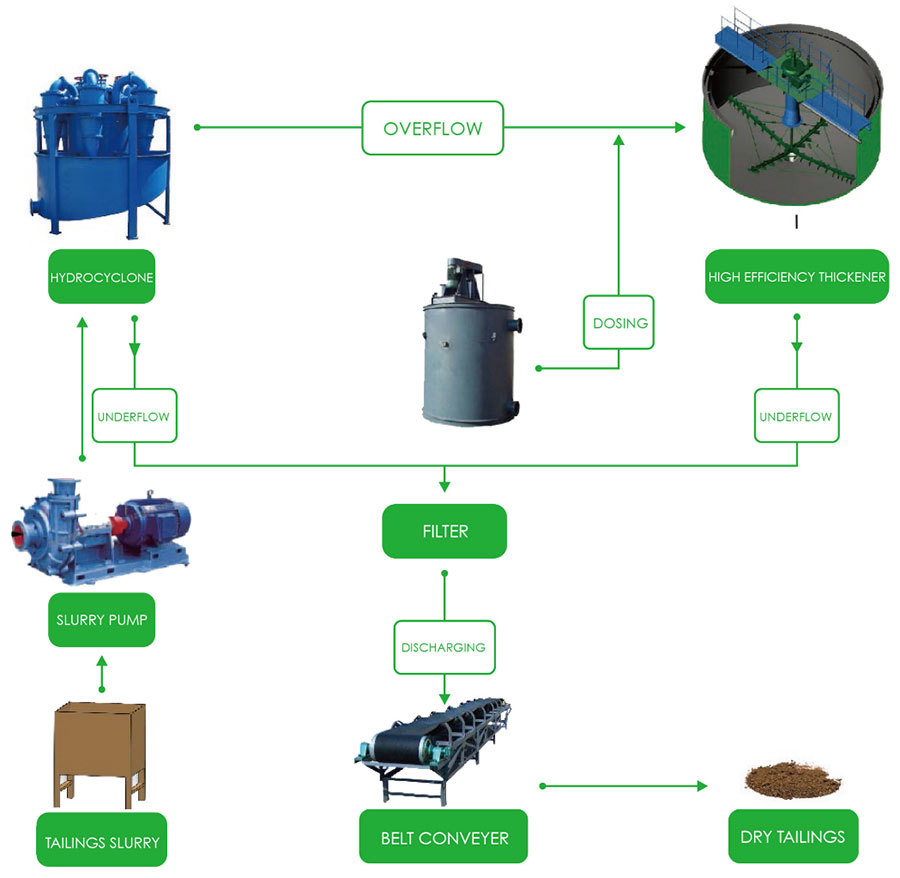

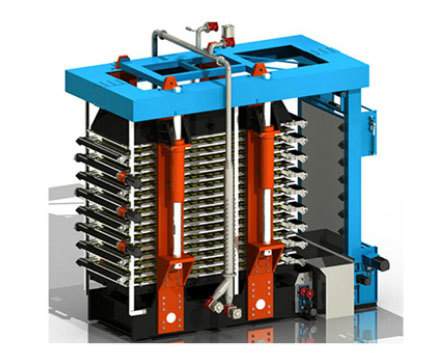

Process Flow Diagram Of Tailings Dewatering

First Proposal:Whole Tailings Dewatering

Second Proposal:Classified Tailings Dewatering

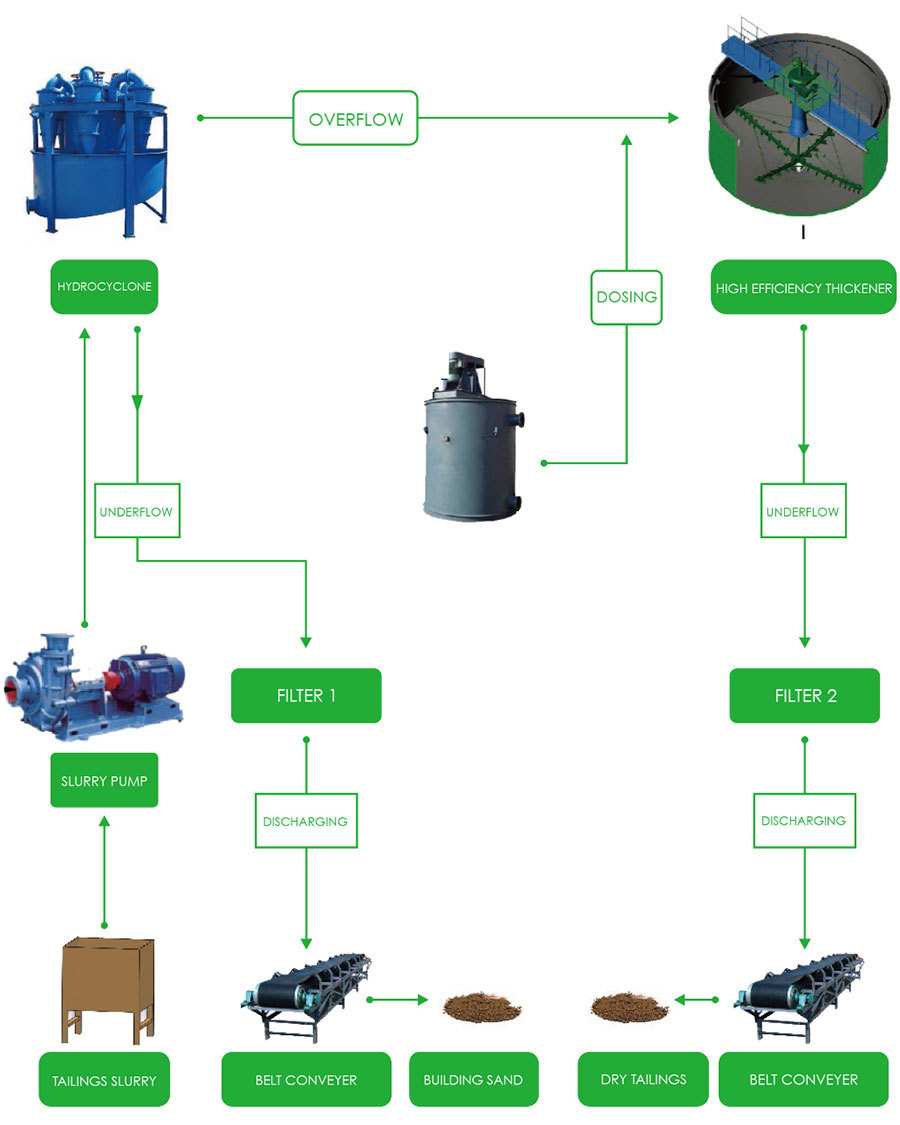

All Kinds Of Filters

according to real situation, adjust different process groups to achieve the best treatment effect.

High Efficient Hydrocyclone

Slurry flows along the line into hydrocyclone under pressure. Under centrifugal force, large particles are thrown to the wall, move downward with external swirling flow and are discharged from the lower grit chamber to get coarse-grained grit products. Fine particles move upward with the internal swirling flow from the upper overflow pipe to get fine-grained overflow products.

Generally, using a small angle cone or a multi-cone structure hydrocyclone can increase underflow concentration and capacity.

Technical Specification Of Hydrocyclone:

| Model | Inner Diameter(mm) | Slurry Feeding Pressure (MPa) | Capacity (m3/h) | Separation Solid Size (μm) |

| NMT-750 | 750 | 0.03-0.4 | 400-550 | 74-250 |

| NMT-660 | 660 | 0.03-0.4 | 250-360 | 74-220 |

| NMT-610 | 610 | 0.03-0.4 | 200-260 | 74-200 |

| NMT-500 | 500 | 0.03-0.4 | 140-220 | 74-200 74-150 |

| NMT-350 | 350 | 0.03-0.4 | 60-90 | 50-150 50-120 |

| NMT-300 | 300 | 0.05-0.4 | 45-80 | 50-150 40-100 |

| NMT-250 | 250 | 0.05-0.4 | 40-65 | 40-100 30-100 |

| NMT-200 | 200 | 0.05-0.4 | 25-40 | 40-100 30-100 |

| NMT-150 | 150 | 0.05-0.4 | 11-20 | 30-74 20-74 |

| NMT-125 | 125 | 0.05-0.4 | 8-15 | 20-100 20-74 |

| NMT-100 | 100 | 0.05-0.4 | 5-12 | 10-100 10-74 |

GNZ Center Drive High Efficiency Thickener

GNZ center drive high efficiency thickener adopts modular design, the whole machine consists of modules such as tank body, support, drive, receiving, discharging, truss, lifting and so on. It has many optimizations in feeding, discharging, overflowing, controling and other aspects. The new structure and control method are more conducive to accelerate material settlement, improve processing capacity of per unit area and reduce overflow turbidity.

Application Fields:

1. Concentrate concentrating, washing and dewatering of wet beneficiation operations, concentrating and dewatering of tailings;

2. Suitable for concentration and purification of solid slurry in coal, steel, chemical, building materials, cement, sewage treatment and other industries, according to different materials and process conditions;

3. Widely used in concentration of metal & non-metal, and concentration of high concentration conveying system of metal & non-metal tailings.

Features:

1. Combining sedimentation theory and design idea of high efficiency thickener, processing capacity of per unit area is large, dewatering effect is good and efficient operation can be realized conveniently;

2. Modular design, to achieve a perfect combination of machine, electricity and liquid;

3. Full-featured serialized control system to maximize the processing capacity of thickener and prevent rake crushing accidents effectively;

4. Comprehensive troubleshooting plan to ensure thickener runs without worry.

GNZ Technical Specification:

| Basic Data | Model | |||||||||||||

| GNZ-3 | GNZ-6 | GNZ-9 | GNZ-12 | GNZ-18 | GNZ-18 | GNZ-24 | GNZ-30 | GNZ-38 | GNZ-45 | GNZ-53 | GNZ-60 | GNZ-75 | ||

| inner diameter of concentration pool(m) | 3.6 | 6 | 9 | 12 | 18 | 20 | 24 | 30 | 38 | 45 | 53 | 60 | 75 | |

| depth of concentration pool(m) | 2.7 | 3.4 | 3.7 | 3.95 | 4.4 | 4.5 | 4.9 | 5.3 | 6.15 | 7.2 | 8.0 | 8.9 | 8.9 | |

| settling area(m2) | 10 | 28 | 63 | 113 | 254 | 314 | 452 | 700 | 1134 | 1590 | 2205 | 2826 | 4416 | |

| outline dimension | L | 3.90 | 6.6 | 11 | 15 | 21 | 23 | 27 | 33 | 41 | 48 | 57 | 64 | 79 |

| H | 4.80 | 5.50 | 5.80 | 6.90 | 8.0 | 8.4 | 9.0 | 9.50 | 10.95 | 12 | 12 | 13 | 14 | |

| Note: Anti-corrosion type is used for non-neutral medium and its exposed surface adopts heavy anti-corrosion coating process of zinc-rich primer & chlorinated chloroprene rubber paint or specific ship paint. The overflow surface is coated with high performance, wear resistant, acid & alkali resistant rubber layer. Both exposed and overflow surfaces can use a protective layer suitable for your working medium, depending on your requirements. | ||||||||||||||

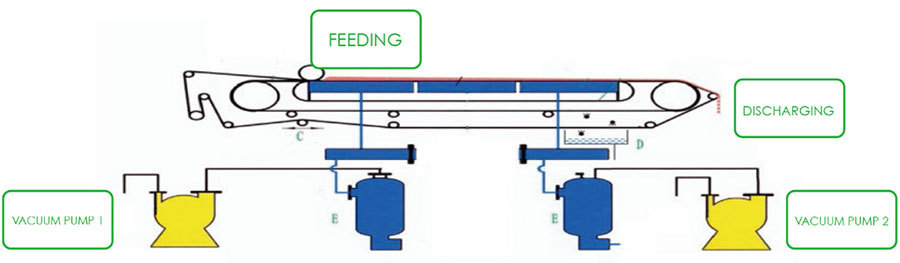

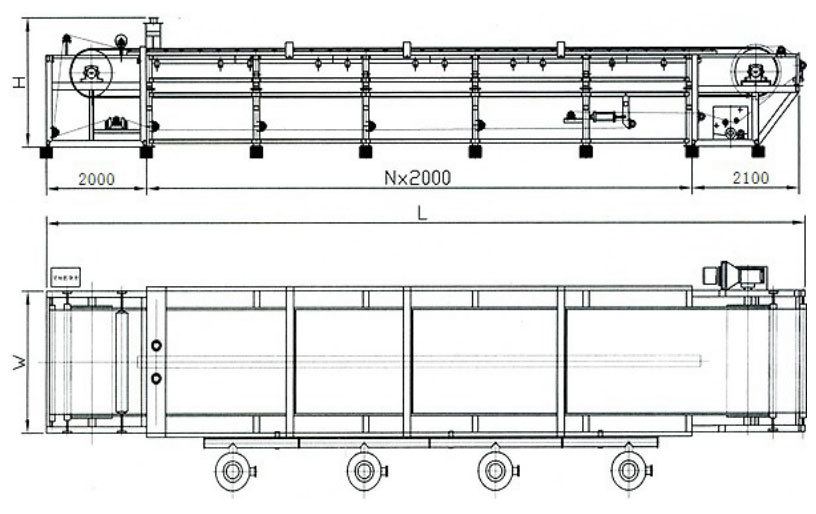

Tailings Vacuum Belt Filter

Operating Principle:

This equipment adopts the fixed vacuum chamber, the rubber belt is drived by the gearbox and running continuously on the vacuum chamber, the cloth moving synchronously on the rubber belt. The friction belt on the slipway of vacuum chamber forming a water sealing structure with rubber belt. The slurry feeding on the cloth smoothly and evenly by feeding hopper.when the vacuum chamber connect with vacuum system, the filtering area with vacuum suction will be formed on the rubber belt, the filtrate pass through the cloth and flow to the grooves and holes of rubber belt to vacuum chamber, the solids formed a cake on the surface of cloth. The filtrate in the vacuum chamber discharged by the vacuum tank. Moving by the rubber belt, the cake moving to the cake washing area and drying area sequentially, then enter into cake discharging area. After discharging cake, the cloth washed by washing system and enter into next filtering cycle.

Features:

●Feeding, filtration, cake washing, cake drying, discharging, cloth regeneration, cloth redirection automatically, the degree of automation is extremely high.

●The filter mother liquor and cake washing liquid can be collected separately, and cake washing can achieve multichannel advection and countercurrent washing, washing liquid of each section can be collected separately.

●The remote control and local control can be exchanged to achieve unmanned operations.

●The running speed of rubber belt can be regulated steplessly within a certain range, and the thickness of cake can be adjusted according to filtering performance of materials to achieve the best filtering effect and strong adaptability.

●The whole machine adopts frame modular design, which is very convenient for transportation, installation and maintenance of equipment.

●Use high pressure water for cloth washing to increase the cloth regenerative effect and the life span.

●Filtrate discharge types include automatic discharge, high level discharge and auxiliary discharge.

●Gas cover or aluminum plastic Windows can be designed partial closed or totally enclosed for partial insulation or the centralized collection for the volatile gas or steam of slurry, in order to have a clean production.

Technical Specification

| Filtrating Area(m2) | Effective Width | Effective Length | Frame Length | Frame Width | Frame Height (m) | Weight(t) | Vacuum Consumption(m3/min) |

| 2 | 500 | 4000 | 8100 | 1100 | 2070 | 5.5 | 8 |

| 3 | 6000 | 10100 | 6 | 12 | |||

| 4 | 8000 | 12100 | 6.5 | 16 | |||

| 5 | 10000 | 14100 | 7 | 18 | |||

| 6 | 12000 | 16100 | 7.6 | 22 | |||

| 8 | 1000 | 8000 | 12100 | 1600 | 2070 | 8.8 | 25 |

| 10 | 10000 | 14100 | 9.6 | 28 | |||

| 12 | 12000 | 16100 | 10.4 | 30 | |||

| 14 | 14000 | 18100 | 11.1 | 33 | |||

| 10.4 | 1300 | 8000 | 12100 | 1900 | 2170 | 9.8 | 28 |

| 13 | 10000 | 14100 | 10.8 | 30 | |||

| 15.6 | 12000 | 16100 | 11.5 | 35 | |||

| 18.2 | 14000 | 18100 | 13.2 | 38 | |||

| 20.8 | 16000 | 20100 | 15.1 | 42 | |||

| 20 | 2000 | 10000 | 14100 | 2700 | 2170 | 14.2 | 40 |

| 24 | 12000 | 16100 | 17.8 | 48 | |||

| 28 | 14000 | 18100 | 20.2 | 52 | |||

| 32 | 16000 | 20100 | 23.6 | 65 | |||

| 20 | 2500 | 8000 | 12100 | 3200 | 2270 | 14.8 | 40 |

| 25 | 10000 | 14100 | 18.6 | 50 | |||

| 30 | 12000 | 16100 | 22.2 | 60 | |||

| 35 | 14000 | 18100 | 26 | 70 | |||

| 40 | 16000 | 20100 | 29.8 | 80 | |||

| 50 | 20000 | 24100 | 41 | 95 | |||

| 30 | 3000 | 10000 | 14100 | 3750 | 2270 | 22.8 | 60 |

| 36 | 12000 | 16100 | 27.5 | 72 | |||

| 42 | 14000 | 18100 | 32.5 | 85 | |||

| 54 | 18000 | 22100 | 45 | 105 | |||

| 60 | 20000 | 24100 | 50.5 | 120 | |||

| 48 | 4000 | 12000 | 16100 | 4800 | 2470 | 39.5 | 92 |

| 56 | 14000 | 18100 | 46.8 | 110 | |||

| 64 | 16000 | 20100 | 52.6 | 120 | |||

| 72 | 18000 | 22100 | 58.3 | 145 | |||

| 80 | 20000 | 24100 | 63 | 160 | |||

| 114 | 4500 | 32500 | 41200 | 7100 | 5500 | 70 | 360 |

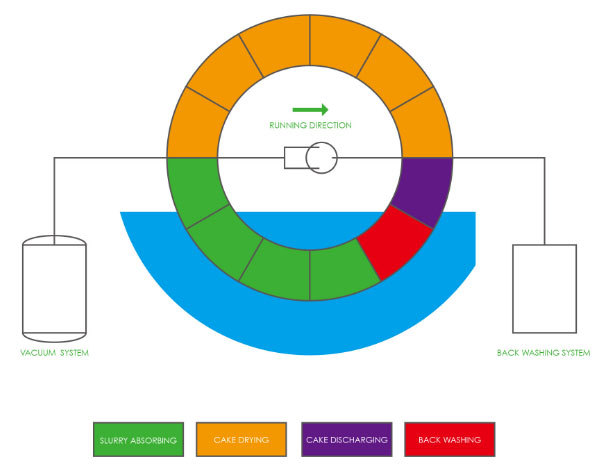

CF Ceramic Disc Filter

Operation Principle

The ceramic plate immersed in the slurry tank, and the material cake layer formed on its surface under vacuum negative pressure and adsorbed by the plate capillary. The liquid passes through the inside of the plate and pipes to the vacuum tank and discharge out.The cake on the plates running by main roller to drying area, and continues to dehydrate under vacuum function. Then running to cake discharging area (without vacuum) to discharge the cake by ceramic scraper.After discharging, the ceramic plate running to the back washing area, the process water or compressed air will be enters to the ceramic plate inside by the back washing pipes, and washing the ceramic plate holes from inside to outside.After working for one shift, the ceramic plate should be washed by ultrasonic waves and combined with low concentration acid to ensure its efficiency.

| Model & Area (m2) | Filter Disc/Cycle | Plate Qty./Pcs | Installed Power(kw) | Operating Power(kw) | Main Body(l×w×h)(m) |

| CF-1 | 1 | 12 | 3.5 | 2 | 1.6×1.4×1.5 |

| CF-6 | 2 | 24 | 7 | 6 | 2.4×2.9×2.5 |

| CF-15 | 5 | 60 | 11.5 | 8 | 3.3×3.0×2.5 |

| CF-30 | 10 | 120 | 17.5 | 11.5 | 5.5×3.0×2.6 |

| CF-48 | 12 | 144 | 34 | 24 | 5.7×3.1×3.0 |

| CF-60 | 12 | 144 | 45 | 33 | 6.0×3.3×3.1 |

| CF-80 | 16 | 192 | 63 | 47 | 7.3×3.3×3.1 |

| CF-120 | 20 | 240 | 77 | 57 | 8.5×3.7×3.3 |

| CF-144 | 12 | 144 | 110 | 89 | 8.0×4.9×4.7 |

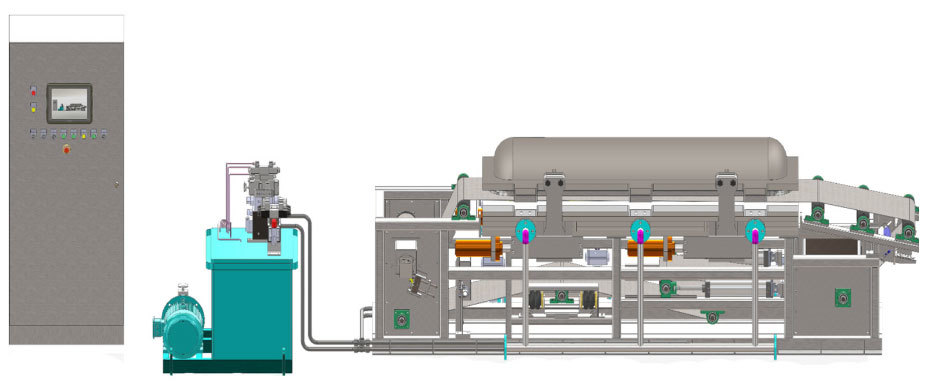

SSY Horizontal Belt Press Filter

SSY Horizontal Belt Press Filter is a new type filter, it consists of main body, electric & pneumatic control system, hydraulic control system, air-drying system and slurry feeding system. During filter working, close the filter chamber first, then feed slurry to chamber by feeding pump with certain pressure. With the help of slurry feeding pump pressure and pressure difference between two sides of filter medium to reach solid-liquid separation, the solids hold in the filter chamber, the filtrate pass through cloth and discharge out. After a certain time, the filtrate can’t flow out, the filtering process finished and stop slurry feeding. Then squeeze by high pressure and use compressed air for drying the cake. Open the filter chamber, drive roller driving the cloth to running forward and discharge the cake with scraper. Use high pressure storm to wash cloth and enter into next filtering cycle.

This filter has the advantages of simple structure, high level automation degree, low failure rate, easy maintenance and so on.

Features:

1.Use automatic high pressure to squeezing the cake, squeeze pressure up to Max. 1.0MPa, use high pressure compressed air to blowing the cake and make the cake moisture as low as possible.

2.Use automatic high-pressure water washing the cloth to ensure the cloth reuse and make the cloth life more longer, filtering efficiency much higher, and saving the water consumption for filter.

3.Open & close filter chamber device with short stroke, so it can open and close filter chamber quickly, and shorten the filtering cycle time. Besides, hydraulic system driving cloth running with high speed, so the minimum time for each cycle only need 4 minutes, so this filter can reach a high working efficiency.

4.The locking device for filter chamber can reach self-locking function. It with full automatic intelligent operation, monitoring, safe and reliable.

Technical Specification

| Model | Filtering Area (m2) |

Filter Chamber Volume (m3) |

Feeding Pressure (mPa) |

Press Pressure (mPa) |

Main Power (KW) |

Total Weight (t) |

Outline Dimension (m) |

| SSY-1000 | 5 | 0.25 | 0.5-0.8 | 1.0 | 11 | 11.2 | 6×1.9×2.1 |

| 10 | 0.5 | 0.5-0.8 | 1.0 | 15 | 21.5 | 11.5×1.9×2.1 | |

| 15 | 0.75 | 0.5-0.8 | 1.0 | 18.5 | 32 | 17×1.9×2.1 | |

| 20 | 1.0 | 0.5-0.8 | 1.0 | 18.5 | 42.3 | 22.5×1.9×2.1 | |

| SSY-2000 | 10 | 0.5 | 0.5-0.8 | 1.0 | 15 | 16.8 | 6.5×2.9×2.2 |

| 20 | 1.0 | 0.5-0.8 | 1.0 | 22 | 32.5 | 12×2.9×2.2 | |

| 30 | 1.5 | 0.5-0.8 | 1.0 | 25 | 48.5 | 17×2.9×2.2 | |

| 40 | 2.0 | 0.5-0.8 | 1.0 | 30 | 63.2 | 23×2.9×2.2 |

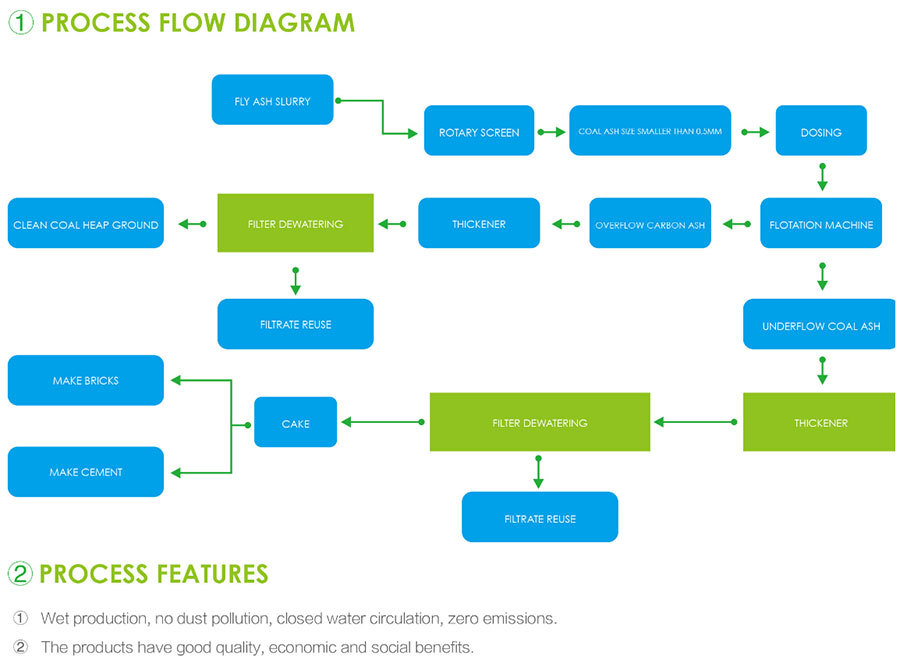

SPF Stack Filter Press

SPF stacked pressure filter is a kind of high-efficiency, energy-saving and intelligent solid-liquid separation equipment. It makes full use of the slurry feeding pump pressure, slurry properties and rubber diaphragm extrusion pressure, and use filter cloth as filter medium to separate the solid and liquid from slurry.

Features

1.use stacked structure for the plates, use auxiliary guide device to make the operation become more stable.

2.integrate filtering, extrusion, washing, air-drying, cake discharging and cloth washing together.

3.the extrusion pressure up to 1.6MPa, it widely used in the field which has different requirements for cake moisture.

4.use hydraulic drive control system, make the operation stable and with low power consumption.

5.integrate PLC, HMI and instruments control system etc. intelligent together, it makes filter more efficient and easier.

6.use high pressure water cleaning device to make the cloth washing more effective.

7.design with circular chamber, the structure more rational, the efficiency more prominent.

Operating Principle:Feeding→Filtering→Extrusion→Cake washing→Air drying→Cake discharging

Technical Specification

| Model | SPFⅠ-1 | SPFⅠ-2 | SPFⅠ-3 |

| filter area(m2) | 1 | 2 | 3 |

| plate size(mm) | 0.5m2/层 | ||

| plate Qty/layer | 2 | 4 | 6 |

| length(m) | 2.5 | ||

| width(m) | 1.5 | ||

| height(m) | 2.0 | 2.2 | 2.5 |

| weight(t) | 8 | 9 | 10 |

| Model SPFⅡ | SPFⅡ-3 | SPFⅡ-6 | SPFⅡ-9 | SPFⅡ-12 | SPFⅡ-15 | SPFⅡ-18 | SPFⅡ-21 | SPFⅡ-24 |

| filter area(m2) | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 |

| plate size(mm) | 1.5m2/层 | |||||||

| plate Qty/layer | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 |

| length(m) | 3.7 | |||||||

| width(m) | 4.1 | |||||||

| height(m) | 2.6 | 2.8 | 3.2 | 3.7 | 4.2 | 4.6 | 5.1 | 5.5 |

| weight(t) | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| Model SPFⅢ | SPFⅢ-18 | SPFⅢ-24 | SPFⅢ-30 | SPFⅢ-36 | SPFⅢ-42 | SPFⅢ-48 | SPFⅢ-54 | SPFⅢ-60 | SPFⅢ-66 |

| filter area(m2) | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 66 |

| plate size(mm) | 3.0m2/层 | ||||||||

| plate Qty/layer | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 |

| length(m) | 5.1 | ||||||||

| width(m) | 5.5 | ||||||||

| height(m) | 4.3 | 4.5 | 4.9 | 5.4 | 5.8 | 6.3 | 6.8 | 7.2 | 7.7 |

| weight(t) | 31 | 33 | 35 | 37 | 39 | 41 | 43 | 45 | 47 |

| ModelSPFⅣ | SPFⅣ-60 | SPFⅣ-72 | SPFⅣ-84 | SPFⅣ-96 | SPFⅣ-108 | SPFⅣ-120 | SPFⅣ-132 | SPFⅣ-144 | SPFⅣ-156 | SPFⅣ-168 |

| filter area(m2) | 60 | 72 | 84 | 96 | 108 | 120 | 132 | 144 | 156 | 168 |

| plate size(mm) | 6m2/层 | |||||||||

| plate Qty/layer | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| length(m) | 7.1 | |||||||||

| width(m) | 5.5 | |||||||||

| height(m) | 5.4 | 5.8 | 6.2 | 6.6 | 6.9 | 7.2 | 7.6 | 7.9 | 8.3 | 8.6 |

| weight(t) | 92 | 96 | 100 | 104 | 108 | 112 | 116 | 120 | 124 | 128 |

Intelligent Horizontal Press Filter

Intelligent press filter is an intelligent horizontal filter press. It uses a pressure difference formed on both sides of filter cloth to achieve solid-liquid separation. The filter contains electric and pneumatic control system, hydraulic system and main machine It can also be used for pressing, washing and drying of high pressure diaphragm.

It is equipped with an automatic discharging device, which solves the problem that traditional horizontal filter press cannot discharge automatically, and it realizes automatic filtering, safe and reliable.

It is equipped with a liquid collecting separating device to ensure cake and filtrate do not interfere with each other.

It is equipped with an automatic cloth cleaning device, which uses high-pressure water to clean, effect is good.

Cloth of this equipment is convenient to replace, labor intensity is small and efficiency is high.

Qingdao Hesheng Intelligent Environmental Protection Equipment Co., Ltd. accumulation and development in tailings comprehensive treatment industry for many years, we have strong market competitiveness with experienced R&D team, advanced automated production equipments and many core technologies in tailings dewatering process. Our company's original tailings dewatering process has a low comprehensive cost, simple, stable and easy to operate. With excellent technical technology, excellent product quality, and complete product categories, the company customizes different equipments according to customer requirements to meet site requirements.

Using Site

Other Tailings Dewatering Processes

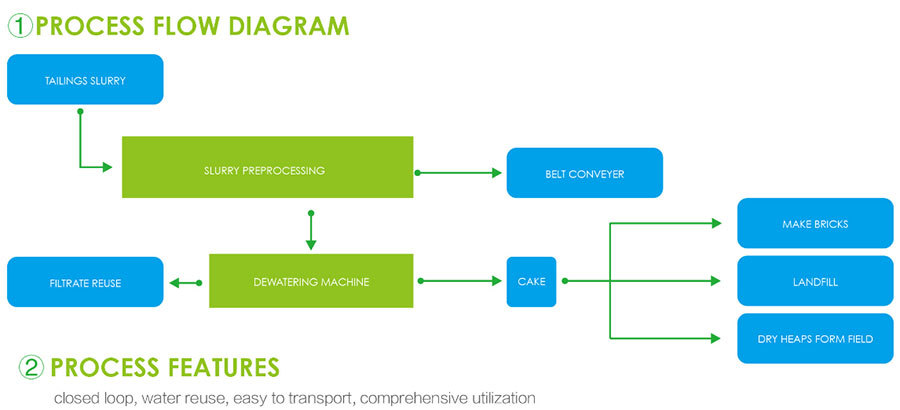

New Process Of Separation And Washing Red Mud

(1)process flow diagram

(2)process features

1. Discharged red mud with alkali can be reduced to: 6kg / t (dry red mud);

2. Without red mud separation tank and washing tank, it can save a lot of construction investment and simplify alumina process to improve production environment, reduce energy consumption greatly and increase alumina recovery efficiency.

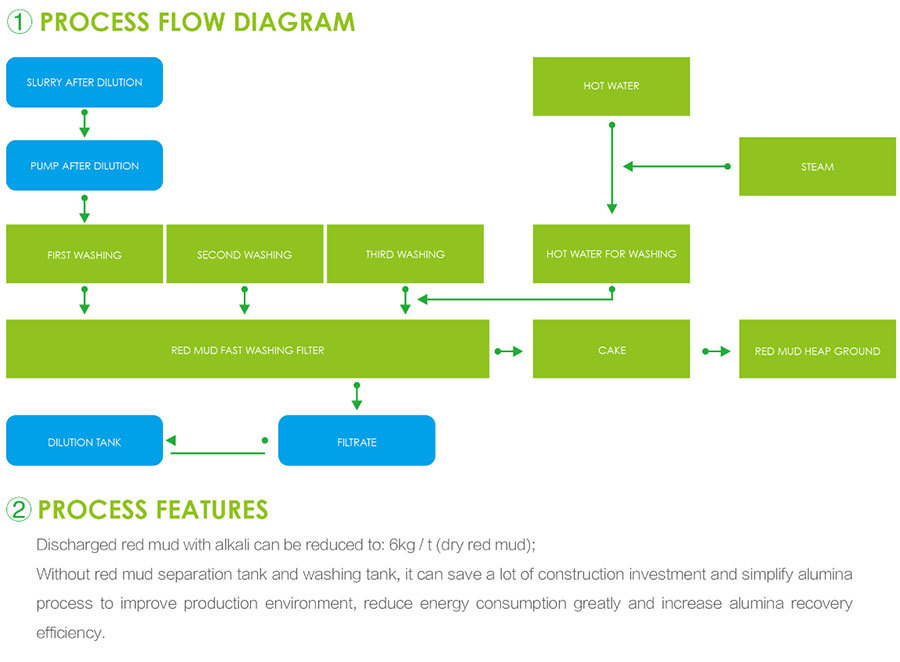

New Process For Comprehensive Utilization Of Ultra-fined Fly Ash (Coal Chemical Fine Slag) Deashing In Coal-fired Power Plants

(1)process flow diagram

(2)process features

1. Wet production, no dust pollution, closed water circulation, zero emissions.

2. The products have good quality, economic and social benefits.

Key:

Related Products

undefined

Message