PRODUCT CENTER

——

Details

★ Brief Introduction

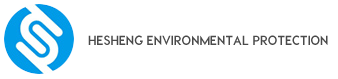

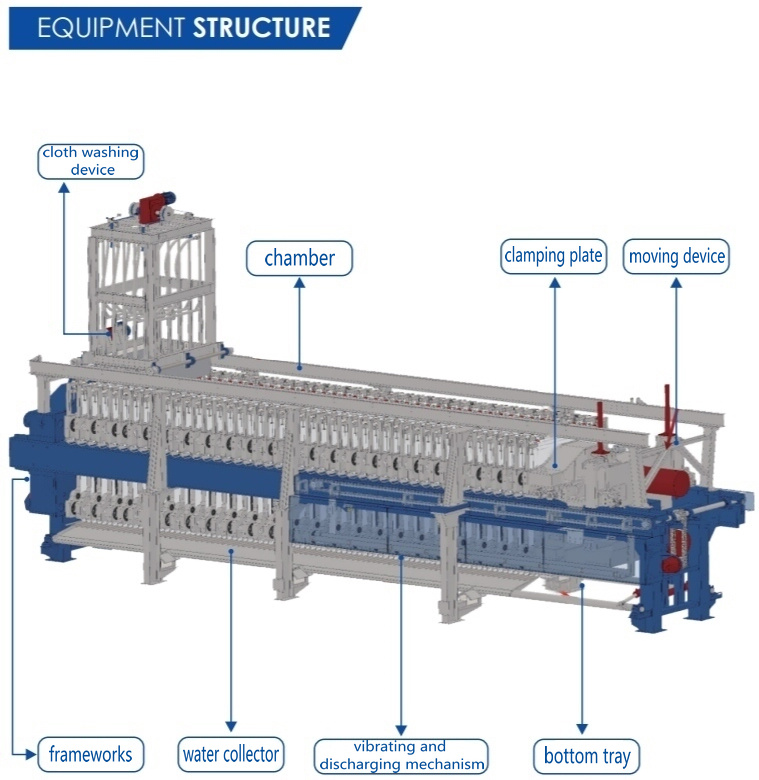

HPF Intelligent Filter Press is an automatic and high-efficient environmental protection solid-liquid separation equipment. It can open and close all plates together at one time, and finish slurry feeding, filtering, extrusion, washing, air-drying, cake discharging etc. process automatically. The filter contains main machine, automatic washing system, electric and pneumatic control system, hydraulic system. When start the filter use mechanical drive device to pull the hydraulic cylinder first, and drive the plates close to setting position, after locking device locking the hydraulic cylinder, piston rod reaching out, filter press plates mutual compression to form chamber between each two plates and sealing around. Use slurry feeding pump to feed slurry with a certain pressure to each chamber, solids will be accumulated by cloth to form a cake, liquid will pass through cloth and flow out by filtrate pipes. Feeding high-pressure compressed air to diaphragm and squeezing the cake, then use high-pressure compressed air to air-drying the cake. At last, use drive device to open the chamber, and discharge the cake with gravity. This filter press has the advantages of simple structure, high automatic level, open & close plates with short time and easy maintenance.

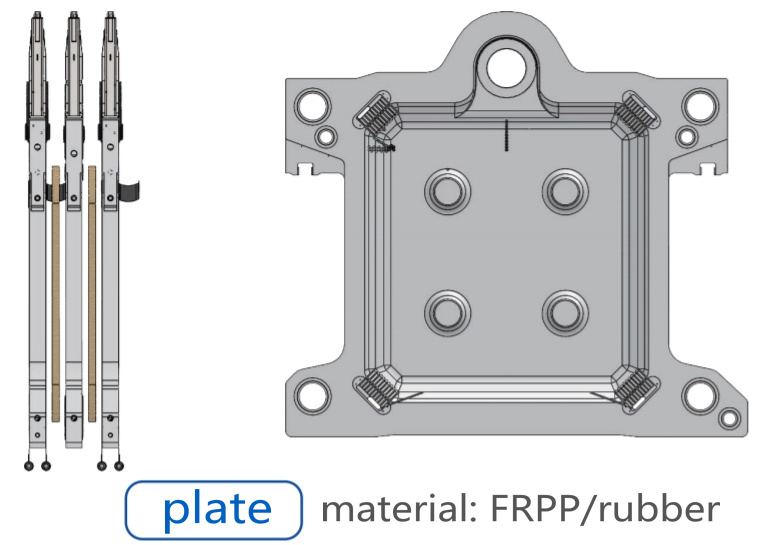

The filtration unit of HPF Intelligent Filter Press is formed by alternate arranged diaphragm and chamber type filter plates and filter medium between them to form groups of chambers, the volume of each chamber can be changed in a certain range. During operation, press the slurry by the feeding pump into the filter chamber to form fluid pressure, filtrate through the cloth and flow along the diversion gap to corner channel of plates, discharge filtrate concentrated. Solids will be accumulated on the cloth to form cake until full of the chamber, that’s finish the filtering. After that, the squeezing medium (water or compressed air) will enter into the diaphragm cavity through squeezing channel and form pressure to squeezing the liquid out from cake to corner channel. Then feeding high-pressure compressed air to one side of cake to air-drying the cake. Finally, open all the plates and discharge cake, washing cloth, reclose plates and enter into next cycle.

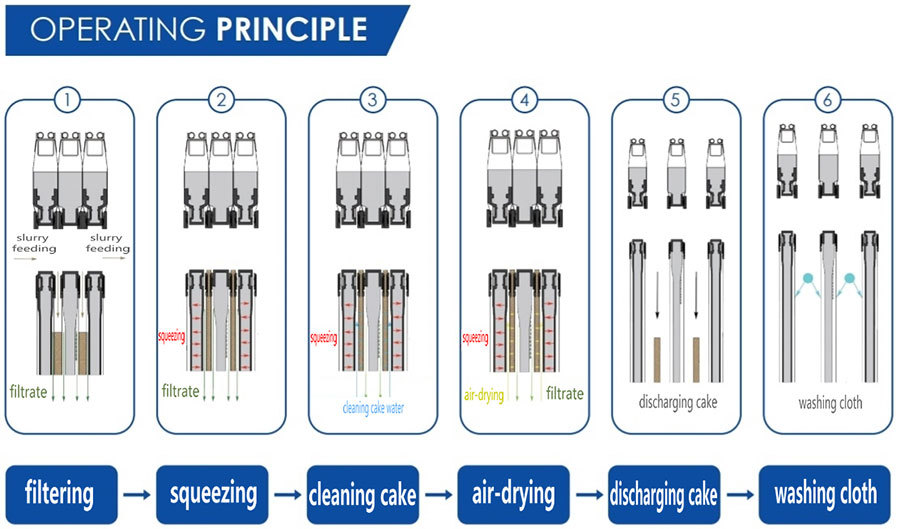

★ Process Diagram

★ Features

● Hydraulic hold-down device which can realize mechanical moving to make the plates open and close quickly.

● Diaphragm squeezing the cake with 1.6MPa pressure, it can reach low cake moisture.

● High-pressure automatic cloth washing device can washing the cloth thoroughly and ensure the cloth recycle.

● Vibrator cake discharging device can make the cake discharge easily and do not need humans.

● The cloth can be disassembled and assembled directly on the top, change cloth becomes more easily and quickly.

● Automatic open & close tray device can collect liquid separately to ensure the cake and liquid will not mix together.

● Intelligent control system to make the equipment operation safe and reliable.

★ Application

Chemical industry, metallurgy industry, mining, water resource field, food industry, pharmaceutical industry, power industry, environmental protection industry and so on. Base on the strong adaptability of this equipment, it almost can be used in solid-liquid separation of all the industries.

★ Filtering Darts

★ Site Photos

Key:

Related Products

undefined

Message