PRODUCT CENTER

——

Details

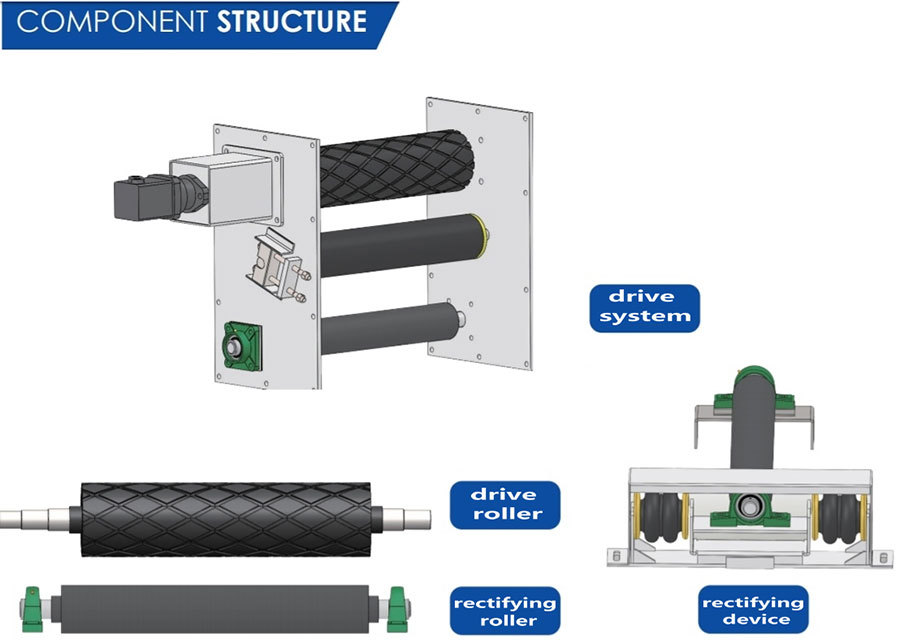

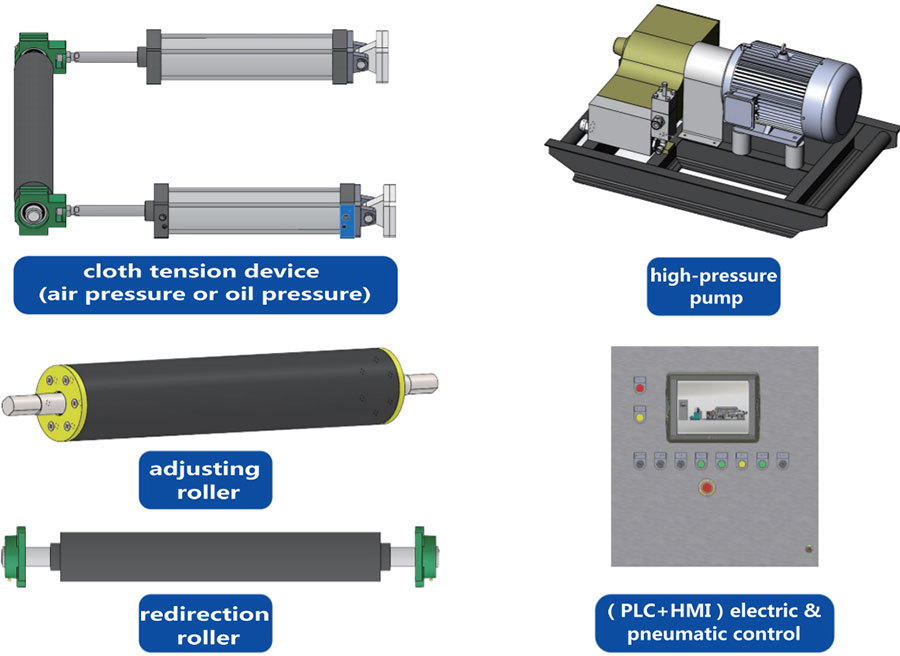

★ Brief Introduction

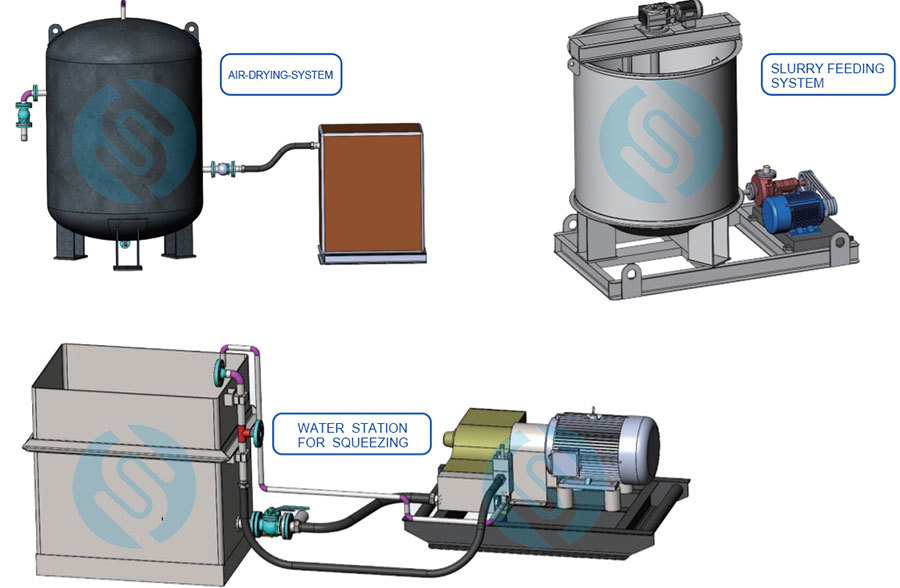

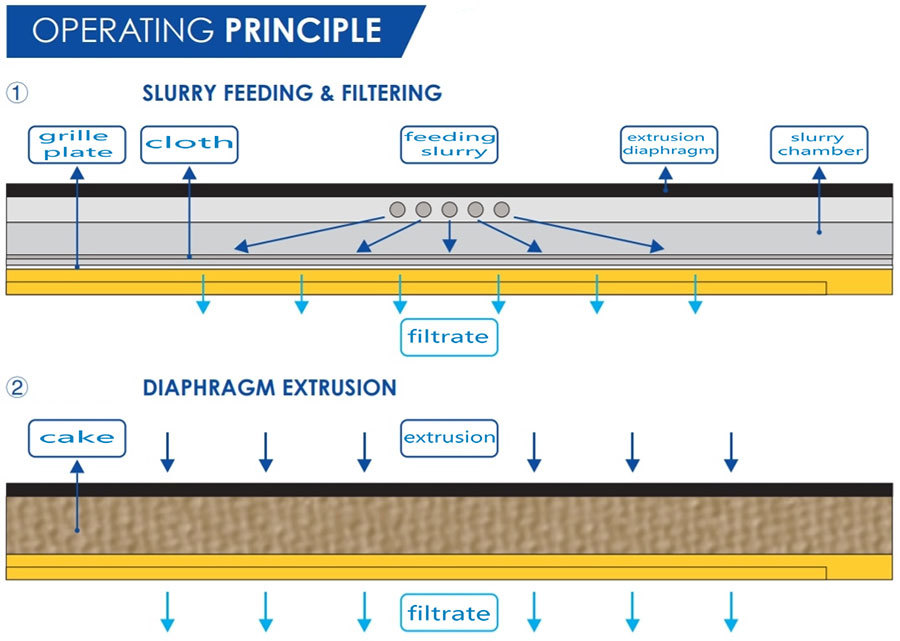

SSY Horizontal Belt Press Filter is a new type filter, it consists of main body, electric & pneumatic control system, hydraulic control system, air-drying system and slurry feeding system. During filter working, close the filter chamber first, then feed slurry to chamber by feeding pump with certain pressure. With the help of slurry feeding pump pressure and pressure difference between two sides of filter medium to reach solid-liquid separation, the solids hold in the filter chamber, the filtrate pass through cloth and discharge out. After a certain time, the filtrate can’t flow out, the filtering process finished and stop slurry feeding. Then squeeze by high pressure and use compressed air for drying the cake. Open the filter chamber, drive roller driving the cloth to running forward and discharge the cake with scraper. Use high pressure storm to wash cloth and enter into next filtering cycle.

This filter has the advantages of simple structure, high level automation degree, low failure rate, easy maintenance and so on.

★ Equipment Features

● Use automatic high pressure to squeezing the cake, squeeze pressure up to Max. 2.0MPa, use high pressure compressed air to blowing the cake and make the cake moisture as low as possible.

● Use automatic high-pressure storm washing the cloth to ensure the cloth reuse and make the cloth life more longer, filtering efficiency much higher, and saving the water consumption for filter.

● Open & close filter chamber device with short stroke, so it can open and close filter chamber quickly, and shorten the filtering cycle time. Besides, hydraulic system driving cloth running with high speed, so the minimum time for each cycle only need 4 minutes, so this filter can reach a high working efficiency.

● The locking device for filter chamber can reach self-locking function. It with full automatic intelligent operation, monitoring, safe and reliable.

● This filter has simple structure, low failure rate and convenient maintenance.

★ Technical Specification

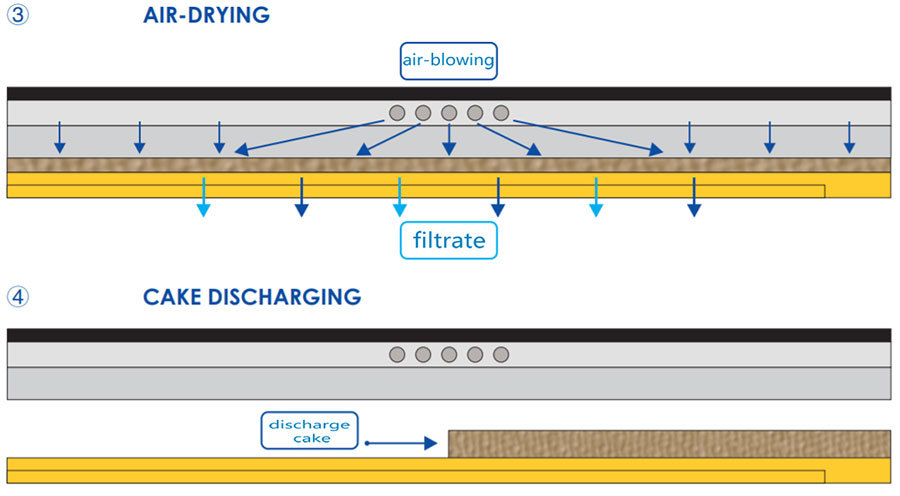

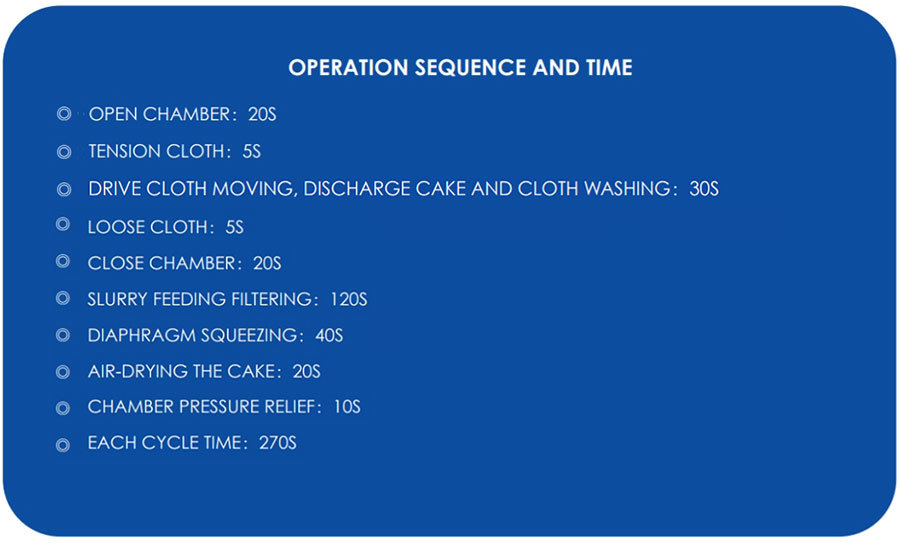

(1)Operation sequence and time

(2)Technical specification list

| Model | Filtering area (M2) |

Cake volume (M3) |

Feeding pressure (MPa) |

Squeezing pressure (MPa) |

Main power (KW) |

Total weight (Kg) |

| SSY/1000 | 5 | 0.3 | 0.5-0.8 | 2 | 10.5 | 6300 |

| 10 | 0.6 | 0.5-0.8 | 2 | 18 | 12500 | |

| 15 | 0.9 | 0.5-0.8 | 2 | 22.5 | 18200 | |

| SSY/1500 | 7.5 | 0.45 | 0.5-0.8 | 2 | 17 | 9000 |

| 15 | 0.9 | 0.5-0.8 | 2 | 22.5 | 17600 | |

| 22.5 | 1.35 | 0.5-0.8 | 2 | 35 | 27200 | |

| SSY/2000 | 10 | 0.6 | 0.5-0.8 | 2 | 26.5 | 14400 |

| 20 | 1.2 | 0.5-0.8 | 2 | 35 | 28000 | |

| 30 | 1.8 | 0.5-0.8 | 2 | 40.5 | 42000 | |

| 40 | 2.4 | 0.5-0.8 | 2 | 52 | 32000 |

★ Equipment Application

Coal chemical gasification furnace ash water filtration, tailings dewatering, metallurgy industry, mining industry, chemical industry, food industry, coal washing industry, environmental protection industry, power industry, pharmaceutical industry.

Key:

Related Products

undefined

Message