PRODUCT CENTER

——

Details

★ Brief Introduction

DLY-type belt press filter is a high efficient continuous operationsolid-liquid separationequipment, which used in municipal sewage plants, water plants, as well as paper, leather industry,printing, slaughtering,petrochemicals, pharmaceuticals, metallurgy and building material,brewing and food industries’ industrial waste water dewatering process. It also applicated in solid-liquid separation ofindustry production or liquid leaching process and resources recycling.

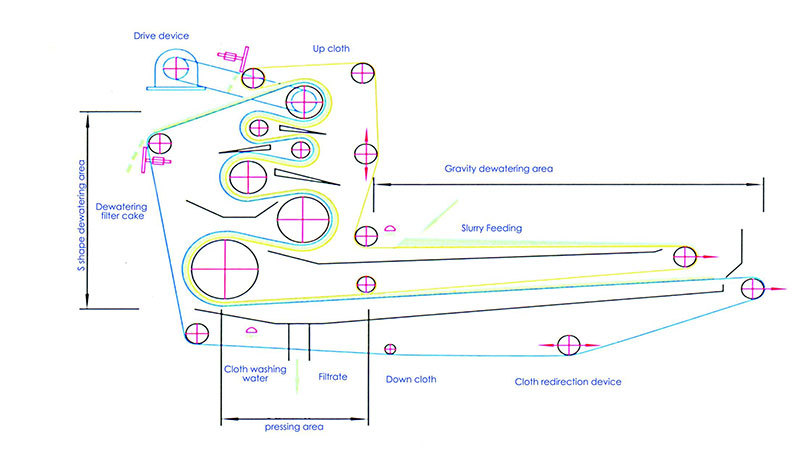

★ Working Principle Diagram

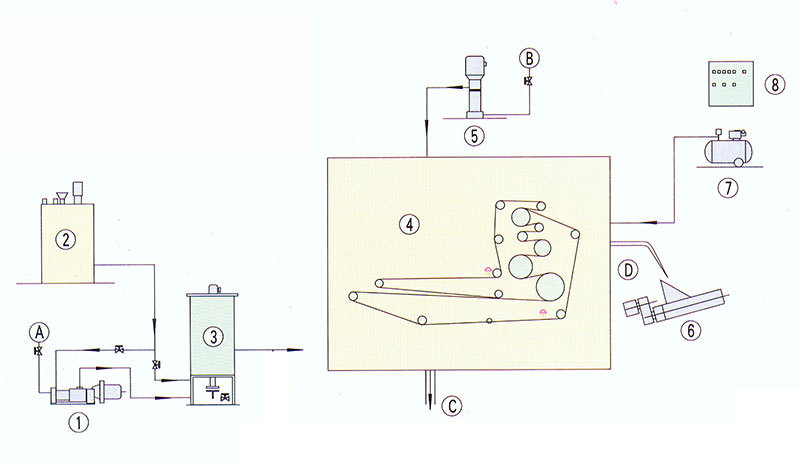

★ Process Flow Diagram

● 1.sludge feed pump

● 2.flocculant solution tank

● 3.flocculant

● 4.belt press filter

● 5.washing water pump

● 6.transfer screw pump

● 7.air compressor

● 8.electric cabinet

● A.sludge inlet

● B.washing water inlet

● C.filtrate discharge out

● D.cake discharge out

★ Technical Features

● Double gravity dehydration, high dehydration efficiency.

● It´s reliable for operation because of "snake" -shape Auto skew redirection.

● It´s convenient for installation and maintenance because of frame structure.

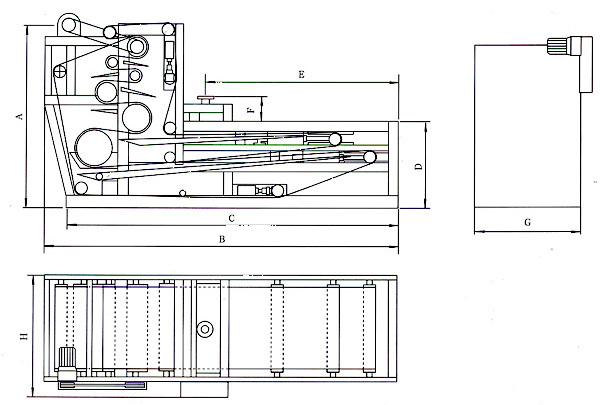

★ Outline Diagram &Technical Parameter

| Parameter | Unit | Model | |||||

| 500 | 1000 | 1500 | 2000 | 2500 | 3000 | ||

| Efficient filter width | mm | 500 | 1000 | 1500 | 2000 | 2500 | 3000 |

| Filter cloth speed | M/min | 0.6-6 | 0.6-6 | 0.6-6 | 0.6-6 | 0.6-6 | 0.6-6 |

| Main motor power | Kw | 1.1 | 1.5 | 2.2 | 2.2 | 3.0 | 3.0 |

| Weight | T | 2.2 | 2.7 | 3.2 | 3.7 | 4.9 | 5.7 |

| Disposal capability | M /h | 2-4.5 | 4-8 | 7.5-12 | 10-17 | 15-21 | 18-25 |

| Washing water consumption | L/min | 30-50 | 60-75 | 80-100 | 120-130 | 140-160 | 180-200 |

| Frame outline(mm) | A | 2230 | 2230 | 2230 | 2230 | 2230 | 2230 |

| B | 4500 | 4500 | 4500 | 4500 | 4500 | 4500 | |

| C | 4275 | 4275 | 4275 | 4275 | 4275 | 4275 | |

| D | 1080 | 1080 | 1080 | 1080 | 1080 | 1080 | |

| E | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | |

| F | 350 | 350 | 350 | 350 | 350 | 350 | |

| G | 1150 | 1650 | 3150 | 2650 | 3150 | 3650 | |

| H | 1450 | 1950 | 2450 | 2950 | 3450 | 3950 | |

Key:

Related Products

undefined

Message