PRODUCT CENTER

——

Details

Thickener is a equipment that works by gravity sedimentation of solid particles. It can achieve continuous concentration and clarification of mining slurry, and is widely used in mining, metallurgy, chemical, coal, environmental protection and other industries.

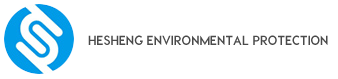

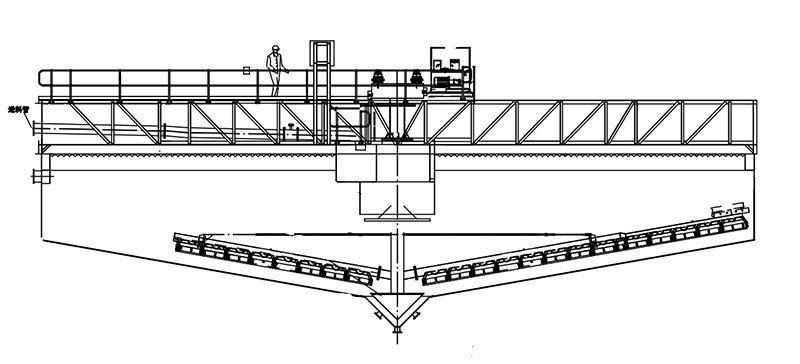

GNZ Series Central Drive Thickener

★ Brief Introduction

GNZ series central drive thickener is a new series of continuous concentration and clarification equipment independently designed by our R&D center based on the series and technical requirements of GB/T10605-2003 and JB/T 11004-2010.

This series of product adopts modular design, the whole machine consists of modules such as tank body, support, drive, receiving, discharging, truss, lifting and so on. According to your needs, we can supply two types: central hydraulic drive high efficiency thickener and central motor drive high efficiency thickener. The new structure and control method are more conducive to accelerate material settlement, improve processing capacity of per unit area and reduce overflow turbidity.

★ Application Field

GNZ series thickener is mainly used for concentrate concentrating, washing and dewatering of wet beneficiation operations, concentrating and dewatering of tailings, and is also widely used in concentration and purification of solid slurry in coal, steel, chemical, building materials, cement, sewage treatment and other industries.

★ Features

1. Combining sedimentation theory and design idea of high efficiency thickener, processing capacity of per unit area is large, dewatering effect is good and high efficient operation can be realized conveniently.

1) Center buffer deep part slurry feeding, absolutely no impact when receiving slurry;

2) Hydraulic center drive with automatic truss lifting protection function;

3) Adopting center inverted cone type sludge collecting tank to compress discharge material twice, concentration is higher and more stable;

4) Reasonable structure of slurry reforming is more conducive to the improvement of concentration efficiency;

5) Outer overflow groove around design makes a larger effective sedimentation area and clearer filtrate;

6) Multi-point flocculant addition way;

7) Heavy duty slewing support is adopted for durability and trouble-free operation;

★ Naming Rules

Model naming rules of GNZ series central drive thickener:

★ GNZ Series Hydraulic Drive Thickener Basic Parameter

| Basic data | Model | |||||||||||||

| GNZ-3 | GNZ-6 | GNZ-9 | GNZ-12 | GNZ-18 | GNZ-18 | GNZ-24 | GNZ-30 | GNZ-38 | GNZ-45 | GNZ-53 | GNZ-60 | GNZ-75 | ||

| Inner diameter of concentration pool(m) | 3.6 | 6 | 9 | 12 | 18 | 20 | 24 | 30 | 38 | 45 | 53 | 60 | 75 | |

| Depth of concentration pool(m) | 2.7 | 3.4 | 3.7 | 3.95 | 4.4 | 4.5 | 4.9 | 5.3 | 6.15 | 7.2 | 8.0 | 8.9 | 8.9 | |

| Settling area(㎡) | 10 | 28 | 63 | 113 | 254 | 314 | 452 | 700 | 1134 | 1590 | 2205 | 2826 | 4416 | |

| Lifting height (mm) | 300 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | |

| Lifting speed mm/min | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | |

| Truss per revolution time (min) | 1.4-3.2 | 2.3-5.4 | 3.5-8.1 | 4.7-11 | 7.0-16.2 | 7.8-18 | 9.4-22 | 11.5-27 | 15-36 | 20-48 | 26-67 | 26-67 | 26-67 | |

| Drive motor power / kW | 1.1 | 1.1 | 3 | 3 | 5.5 | 5.5 | 7.5 | 7.5 | 15 | 15 | 18.5 | 18.5 | 18.5 | |

| Spindle maximum torque (kNm) | 8.86 | 14.55 | 60.37 | 81.07 | 221.4 | 246.7 | 405.3 | 496 | 1294 | 1725 | 2765 | 2765 | 2765 | |

| Drive oil pump displacement ml/r | 2.5 | 2.5 | 10/13 | 10/13 | 13/16 | 13/16 | 16/25 | 16/25 | 40 | 40 | 40 | 40 | 40 | |

| Hydraulic motor displacement ml/r | 80 | 80 | 100×2 | 100×2 | 235×2 | 235×2 | 594×2 | 594×2 | 683×4 | 683×4 | 1000×4 | 1000×4 | 1000×4 | |

| Outline dimension (m) | L | 3.90 | 6.6 | 11 | 15 | 21 | 23 | 27 | 33 | 41 | 48 | 57 | 64 | 79 |

| H | 4.80 | 5.50 | 5.80 | 6.90 | 8.0 | 8.4 | 9.0 | 9.50 | 10.95 | 12 | 12 | 13 | 14 | |

| Note: Anti-corrosion type is used for non-neutral medium and its exposed surface adopts heavy anti-corrosion coating process of zinc-rich primer & chlorinated chloroprene rubber paint or specific ship paint. The overflow surface is coated with high performance, wear resistant, acid & alkali resistant rubber layer. Both exposed and overflow surfaces can use a protective layer suitable for your working medium, depending on your requirements. | ||||||||||||||

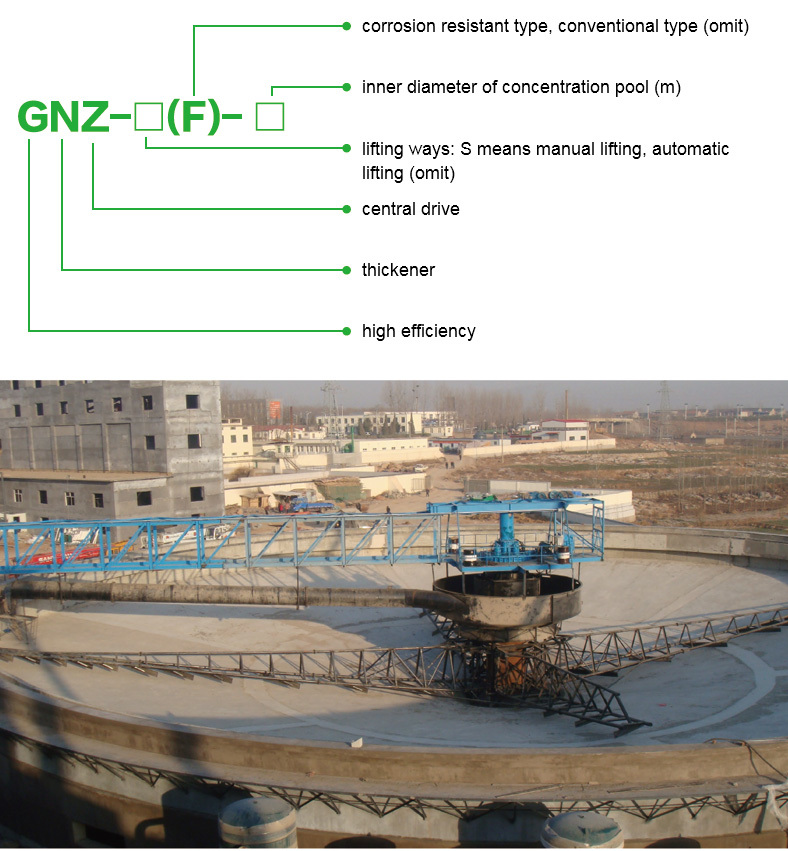

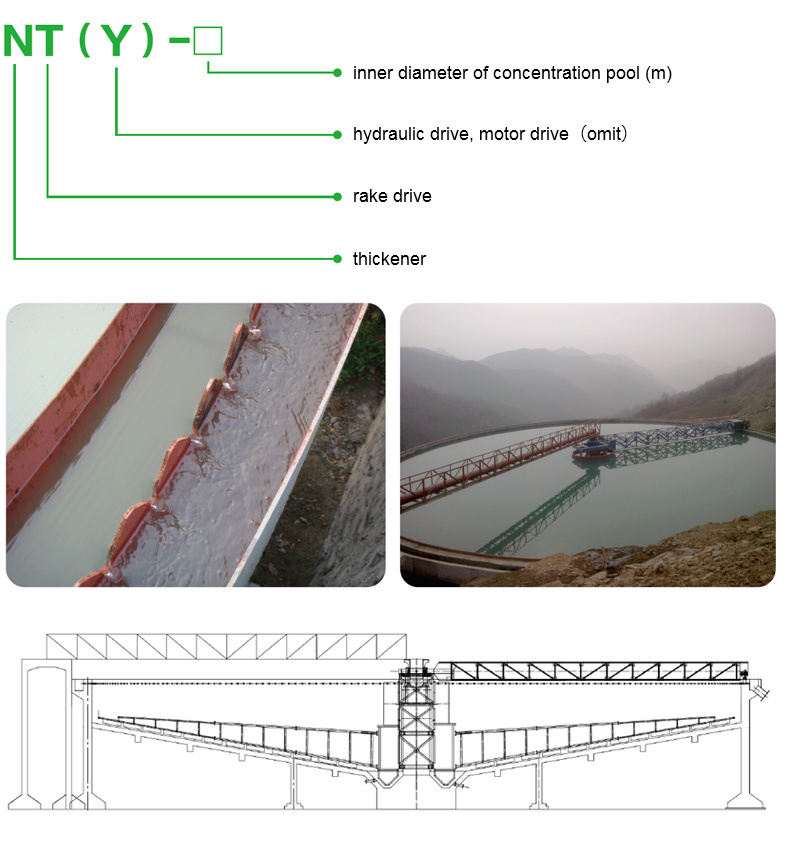

NT Series Peripheral Drive Thickener

★ Brief Introduction

NT series peripheral drive thickener is a new series of continuous concentration and clarification equipment independently designed based on the series and technical requirements of JB/T 6991-2010.

It adopts heavy slewing support and peripheral rack drive form, based on a number of new technologies such as drive torque, sedimentary layer thickness, concentration of mine discharge monitoring of PLC centralized control. This model has features of large drive torque and overload capacity, reliable operation, high concentration efficiency, wide application range, etc.

According to your needs, it can be provided two types: peripheral hydraulic drive high-efficiency thickener, peripheral motor drive high-efficiency thickener.

★ Application Field

NT series peripheral drive thickener is widely used in concentration and purification of solid slurry such as coal, steel, chemical, building materials, cement, sewage treatment, etc. It is an ideal equipment for a two-stage process of concentration and filtration, a three-stage process of concentration, filtration and drying, and a multi-stage washing process.

★ Features

1. Processing capacity of per unit area is larger, dewatering effect is better and high efficient operation can be realized conveniently.

1) Center buffer deep part slurry feeding, absolutely no impact when receiving slurry;

2) Truss is stronger and meets normal and efficient operation meanwhile (adding flocculant);

3) Adopting center inverted cone type sludge collecting tank to compress discharge material twice;

4) Optimized discharge way, discharge concentration is higher and operation is more stable;

5) Reasonable structure of slurry reforming and flow stabilizing is more conducive to the improvement of thickener working efficiency;

6) Multi-point flocculant addition way;

7) Peripheral rack drive, heavy duty slewing support is adopted for durability and trouble-free operation;

★ Naming Rules

Model naming rules of NT series peripheral drive thickener:

★ NT Series Thickener Basic Parameter

| Basic data | Model | |||||||||

| NT-15 | NT-18 | NT-24 | NT-30 | NT-38 | NT-45 | NT-53 | NT-75 | NT-100 | ||

| Inner diameter of concentration pool(m) | 15 | 18 | 24 | 30 | 38 | 45 | 53 | 75 | 100 | |

| Depth of concentration pool(m) | 4.15 | 4.4 | 4.9 | 5.3 | 6.0 | 6.5 | 7.2 | 8.9 | 11.0 | |

| Settling area(㎡) | 175.0 | 254.0 | 452.0 | 700.0 | 1134.0 | 1590.0 | 2200.0 | 4410.0 | 7850.0 | |

| Lifting height (mm) | 450 | 450 | 450 | 500 | 500 | 500 | 500 | 700 | 700 | |

| Lifting speed mm/min | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | ||

| Truss per revolution time (min) | 5.89-13.5 | 7.8-18.0 | 9.4-22.0 | 11.5-27.0 | 15.0-36.0 | 18.0-40.0 | 20.0-48.0 | 26.0-67.5 | 33.0-90.0 | |

| Drive motor power / kW | 5.50 | 5.50 | 7.50 | 7.50 | 11.0 | 11.0-15.0 | 15.0-18.5 | 18.5-22.0 | 18.5-30.0 | |

| Hydraulic pump displacement ml/r | 16 | 16 | 25 | 25 | 25 | 40 | 63 | 63 | 100 | |

| Maximum drive force kN | 20.62 | 22.76 | 28.05 | 27.45 | 41.46 | 57.3 | 66.67 | 78.03 | 94.54 | |

| Outline dimension (m) | L | 15.42 | 18.42 | 24.42 | 30.42 | 38.42 | 45.42 | 53.50 | 75.80 | 100.80 |

| H | 6.15 | 6.40 | 6.90 | 7.50 | 8.20 | 8.72 | 9.70 | 11.90 | 15.00 | |

| Track center diameter / m | DG | 15.38 | 18.38 | 24.38 | 30.38 | 38.38 | 45.38 | 53.38 | 75.38 | 100.38 |

| Rack center diameter / m | DT | 15.63 | 18.63 | 24.63 | 30.63 | 38.63 | 45.63 | 53.63 | 75.65 | 100.65 |

| Note: Anti-corrosion type can be provided for non-neutral medium and its exposed surface adopts heavy anti-corrosion coating process of zinc-rich primer & chlorinated chloroprene rubber paint or specific ship paint. The overflow surface is coated with high performance, wear resistant, acid & alkali resistant rubber layer. Both exposed and overflow surfaces can use a protective layer suitable for your working medium, depending on your requirements. | ||||||||||

GNZS Series Deep Cone Thickener

★ Brief Introduction

GNZS series deep cone thickener is a new type of fully automatic and high performance continuous dewatering equipment designed by contra-flow sedimentation, sedimentation compression theory, combined with inclined plate technology and flocculation assisting sedimentation technology. It has features of small occupied area, large processing capacity of per unit area, wide adaptability range, high underflow concentration, clean overflow, easy automatic control, etc. It is widely used in concentration and purification of solid slurry in metallurgy, mining, coal, steel, chemical, building materials, cement, sewage treatment, etc.

GNZS series deep cone thickener can be provided three types selectively: single gravity discharge type, single forced discharge type and mixed type (gravity discharge type upgrade with discharge truss) according to material characteristics and process conditions of user.

★ Structure Features

1. Slurry feeding channel design makes flocculation stirring strength appropriately, flocculant consumption is less, and effect is better;

2. Steady receiving slurry under dense sedimentary layer, contra-flow flocculation, filtration and sedimentation;

3. Specially designed clean water internal circulation system to make slurry flocculation and sedimentation at optimum concentration;

4. Self-lubricating inclined plate structure shortens settlement distance and increases processing capacity;

5. Accurate measurement and control of the height of dense sedimentary layer to achieve high concentration discharge;

6. Reasonable arrangement of inclined plate and scattering cone is more conducive to scattering and extruding gap water in floc;

7. Modular design, two driving modes: motor and hydraulic stepless speed regulation can be selected arbitrarily;

8. Gravity discharge type can be upgraded to forced discharge type (mixed type) easily;

9. Structural parts realize long-life and reliable operationare according to finite element analysis and optimization;

10. High-strength truss design, smooth operation even in high-viscosity slurry;

11. Intelligent control module achieves constant control of flocculant based on slurry feeding concentration and volume, underflow pump control based on underflow concentration and sedimentary layer height;

12. Gravity discharge type adopts large inclined angle inverted cone discharge, which is more suitable for mine concentrate dewatering and high concentration discharge of tailings;

13. Streamlined truss design, resistance of truss is smaller and efficiency is higher;

★ Strengths

1. High concentration underflow, up to 72%;

2. Low turbidity overflow, overflow water turbidity ≤ 500ppm

3. Large processing capacity of per unit area, up to 180~1500kg/㎡•h

4. Small footprint and fast construction speed;

5. Low operating costs;

6. Fully automatic intelligent operation;

7. Provide a systematic solution for your dewatering process.

8. For special materials, test center will provide you with a no-flocculation deep cone concentration solution through miniaturization test.

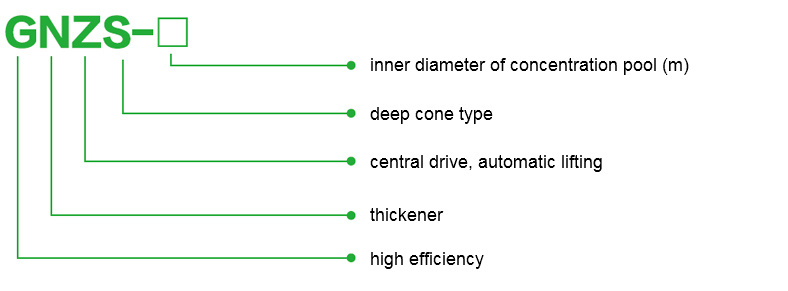

★ Naming Rules

Model naming rules of GNZS series peripheral drive thickener:

★ GNZS Series Thickener Basic Parameter

| Basic data | Model | |||||||||

| GNZS-5 | GNZS-7 | GNZS-9 | GNZS-12 | GNZS-18 | GNZS-24 | GNZS-30 | GNZS-35 | GNZS-40 | ||

| Inner diameter of concentration pool(m) | 5 | 7 | 9 | 12 | 18 | 24 | 30 | 35 | 40 | |

| Depth of concentration pool(m) | 11.8 | 15.6 | 17.3 | 20.00 | 13.0 | 13.80 | 14.70 | 15.50 | 16.33 | |

| Cone, cone angle (°) | 60 | 60 | 60 | 60 | 120 | 120 | 120 | 120 | 120 | |

| Settling area(㎡ | 63.0 | 113.5 | 197.0 | 350.5 | 645.0 | 1024.0 | 1469.0 | 1714.0 | 2355.0 | |

| Lifting height (mm) | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | |

| Lifting speed mm/min | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | |

| Drive motor power / kW | 5.50 | 5.50 | 7.50 | 7.50 | 11.0 | 11.0-15.0 | 15.0-18.5 | 18.5-22.0 | 18.5-30.0 | |

| Truss per revolution time (min) | 2.0-4.5 | 2.7-6.5 | 3.5-8.1 | 4.7-11.0 | 7.0-16.2 | 9.4-22.0 | 11.5-27.0 | 13.5-31.0 | 15.0-36.0 | |

| Drive motor power / kW | 3.0 | 4.0 | 4.0-5.5 | 5.5-7.0 | 7.0-11.0 | 11.0-15.0 | 11.0-15.0 | 11.0-15.0 | 15-18.5 | |

| Hydraulic pump displacement ml/r | 10 | 10 | 16 | 16 | 25 | 40 | 40 | 40 | 40-63 | |

| Maximum drive force kN | 34.5 | 62 | 110 | 189 | 442 | 810 | 992 | 1164 | 1595 | |

| Outline dimension (m) | L | 6.50 | 8.50 | 11.00 | 14.00 | 20.00 | 24.00 | 32.00 | 37.00 | 42.00 |

| H | 12.80/14.30 | 16.60\18.60 | 18.50/20.50 | 21.50/24.00 | 17.00 | 18.00 | 18.70 | 19.50 | 20.50 | |

| Anti-corrosion type can be provided for non-neutral medium and its exposed surface adopts heavy anti-corrosion coating process of zinc-rich primer & chlorinated chloroprene rubber paint or specific ship paint. The overflow surface is coated with high performance, wear resistant, acid & alkali resistant rubber layer. Both exposed and overflow surfaces can use a protective layer suitable for your working medium, depending on your requirements. | ||||||||||

Key:

Related Products

undefined

Message