PRODUCT CENTER

——

Details

★ Brief Introduction

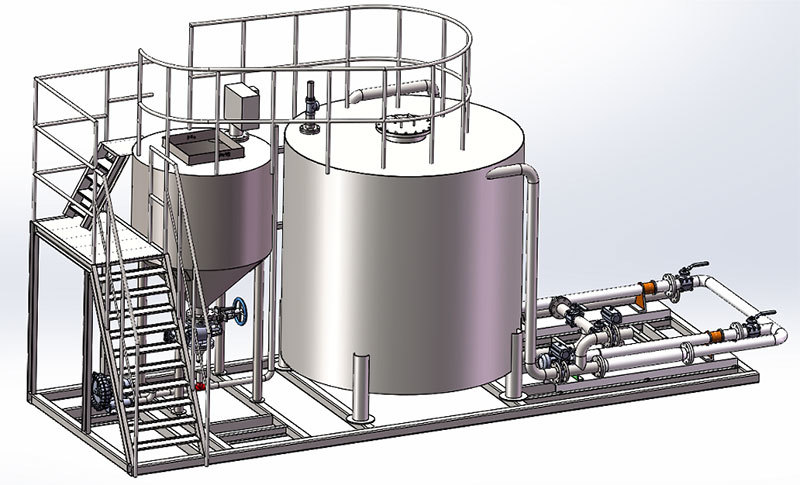

Continuous flocculant quick dissolving device (also called "automatic dosing system") is specially used for feeding, mixing and storing flocculant. It can realize the automatic preparation of flocculant liquid and feeding the prepared solution to industrial process continuously.

Continuous flocculant quick dissolving device with good adaptability and high level of automation overcomes unfavorable factors such as low precision of manual preparation and poor efficiency, and greatly improves flocculant preparation ability. It is more efficient, energy-saving and environmentally friendly than traditional manual preparation.

★ Application

It is mainly used for automatic preparation and feeding coagulant or flocculant to sewage treatment process such as sedimentation, coagulation, air flotation, sludge dewatering, etc. The preparation material is powder or small particle agent, such as powdered polyacrylamide (PAM) etc.

★ Structure

Automatic flocculant formulation device mainly consists of dry powder hopper, star-shaped metering dosing device of dry powder, spiral lifting & conveying device of dry powder, agitation device, agitation tank, heating device, liquid conveying pump and automatic control system.

★ Structure Features

1) Highly integrated equipment, compact structure, small occupied area, light weight, easy for installation, use and maintenance.

2) Continuous preparation, firm equipment structure, easy to operate & maintain & clean, ensure fully dispersing and dissolving.

3) Adopt star-shaped feeder with special structure, feeding powder uniform and reliable.

4) Humidification sprayer and its components (humidifier) for dry powder makes good dissolving effect of dry powder agent.

5) The design of circulating pump is reasonable. During circulating and mixing, not only maximum increase the dissolution speed of agent, but also ensure the molecular chain will not destroyed, agent activity will not degrade and reach high efficiency. Pumping the solution to finished solution tank with the fastest speed to ensure the enough flocculant solution supply.

6) Control cabinet use stainless steel cabinet, with reliable quality, good corrosion resistance, easy maintenance and beautiful appearance.

7) Modular combination and serial configuration can meet different requirements of users.

Integrated pipeline

Assemble metering device on discharge outlet

★ Working Principle

Add flocculant into the dry powder hopper (the upper part of dry powder hopper is installed with bag cutter and grille net). The quantitative water is added to agitation tank during mixing. Dry powder flocculant is sent to agitation tank to mix with water through star-shaped metering dosing device and spiral lifting & conveying device. Stop feeding when dry powder amount reaches the set value. Dry powder flocculant is agitated and mixed with water in agitation tank while heating, and heating device stops working when the set temperature is reached.

Mixing of agitation tank stops working when reaches the set time, and the finished liquid is pumped into flocculant liquid storage tank. Such a mixing cycle is finished, and next mixing cycle is restarted by machine operation under the set procedure. The entire process of mixing is fully automatic, including liquid level control, valve opening and closing, dosing and metering, temperature control, pump start-stop, and can achieve remote control.

★ Performance Features

1) Good corrosion resistance, we can according to different requirements to design different anti-corrosion material.

2) Star-shaped feeder or spiral feeder can transfer with high precision. The concentration of finished solution can be adjusted accurately and stable. It can ensure supply the solution continuously and uninterrupted, and the solution is homogeneous and active.

3) we can according to the real using requirements to adjust the concentration of solution, control the feeding volume of solution accurately to ensure the effect and avoid waste. Reduce granulation (agglomeration) caused by improper manual mixing to block the pipeline or pump, reduce unnecessary maintenance costs and powder consumption expenses.

4) Low power consumption, which is 1/3 to 1/2 of general similar products.

5) Wide range of dissolving concentration, high adaptability of flocculation effect is suitable for various treatment media, the concentration can be adjusted from 0.6 ‰ to 5 ‰, and the maximum solid agent dissolved amount can reach 45kg/h.

6) Accurately liquid level control can ensure the stability of system operation.

7) Equipped with powder level inspector, interlocking control of water feeding system and alarm device to reach high reliability.

8) We have strong technical support, we can according to client requirements to modify the system to 2 tanks, single tank types, and design the whole process.

9) Flexible control, equipped with automatic and manual control.

10) PLC automatic control, the workers only need to put powder to powder tank then no other operate is necessary for them.

11) Good adaptability, equipped with automatic and manual operation, it can be applied to many fields.

★ Equipment Delivery

Key:

Related Products

undefined

Message